For an industrial plant, the electrical system is the most important system as it is the base for running all other systems and networks properly. It is the responsibility of the industrial engineer working in that company that the electrical system of the company keeps working continuously without any trouble. Any problem in the electrical network can lead to huge loss to the company in terms of productivity and efficiency.

For the best working of your industrial electrical network, it is essential that you keep in mind to choose only the best for your industry. You need to be very careful while choosing the components for your high voltage electrical system and choose only the best quality components for your industry. Along with best quality, you also need to choose the right type of components and also proper capacity of load bearing so that it could work under heavy loads put upon it.

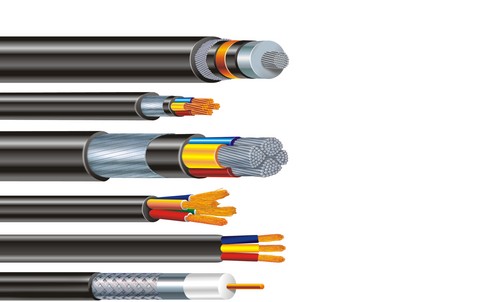

The industrial electrical networks have to bear very heavy loads of thousands of volts, which put them under very high electrical stress. One of the major components that experience most of the electrical stress is the high voltage cables. These cables carry thousands of volts of electricity and are subjected to heavy electrical stress. If you do not take necessary steps to eliminate or reduce this excess of electrical stress, the high voltage cables in your network may face failure very soon and need replacement which would be another loss to the company.

Stress control tubing is a cable accessory that is used for re-distributing the electrical stress from the cables and keeps them safe. The stress control tubing are usually used near the straight through joints and termination kits or the insulation screens of three core cable for best results.

When you are looking for the best solution for your cable accessories, one reliable solution is Compaq. Compaq offers you a wide range of high quality cable accessories and stress control tubing are one of them. Stress control tubing offered by Compaq is made from very high quality material called polyolefin and provide very good functionality. Below are discussed some of the technical features of Compaq stress control tubing.

| Properties | Value | Standard |

| Physical | ||

| Tensile Strength | 12 Mpa (N/mm2)(min) | ASTM D638 |

| Ultimate Elongation | 300%(Min.) | ASTM D638 |

| Longitudinal Change | +10% (max.) | ASTM D2671 |

| Thermal | ||

| Accelerated ageing | (120oC for 500 Hrs) | ASTM D2671 |

| Tensile Strength | 10 Mpa N/mm2 (min.) | ASTM D638 |

| Ultimate Elongation | 300% (Min.) | ASTM D638 |

| Low temperature flexibility(-20oC for 4 Hrs) | No Cracking | ASTM D2671 |

| Heat Shock (250oC for 30 Min.) | No Cracking or Flowing | ESI 09-11 |

| Shrink Temperature | 1250C | IEC 216 |

| Continuous Temperature Limit | -40oC to + 100oC | IEC 216 |

| Electrical | ||

| Volume Resistivity | 1 x 107 Ohm.cm(min.) | ASTM D257 |

| Dielectric Constant | 15 (Min.) | ASTM D150 |

As far as quality of the products offered by Compaq is concerned, all the products are tested in presence of third party experts so that best quality of the products could be ensured.

Author’s Bio: The author is an electrical engineer and loves to write technical articles for compaqinternational Stress control tubing about His job is to provide useful information about various products to the customers through his articles.