For all the wonderful variety and complexity of man-made structures, they become simple and homogeneous when you look closely at their composation. This is not the case with natural materials, which resemble fractals under the microscope with an elaborate supporting structure that goes deeper and deeper.

This is why, despite being inspired to fly by watching birds, man has yet to construct an airplane of feathers that can move with the grace of an eagle.

How do they do it?

Feathers are clearly perfect for flight and insulation. They are self-healing and aerodynamic, lightweight and yet astonishingly strong; however, an understanding of how they do it has been a long time coming.

Using an electron microscope, Theagarten Lingham-Soliar – a materials scientist from South Africa’s Nelson Mandela Metropolitan University – inspected feathers closer than ever before and made a succession of discoveries all the way down to the molecular scale.

The shaft of a feather is called a rachis and the side branches are called barbs. Under an ordinary microscope, you can see barbules that hook the barbs into the firm planes needed for flight.

Fibres in these two orientations somehow withstand the immense stresses of flight, but nobody understood how; nor could they replicate it in man-made materials. Looking deeper, smaller structures were revealed that redistribute the stresses, with a glue-like substance holding the fibres together in one direction but improving movement laterally.

All the components, even in the softest feather, are made of extremely hard keratin. In cross section, the electron microscope reveals this also has a precise supporting structure that endows the almost hollow filaments with strength out of all proportion to their weight. The molecular arrangement of keratin in birds is different from other animals – pleated rather than helical – making it even more perfect for the job.

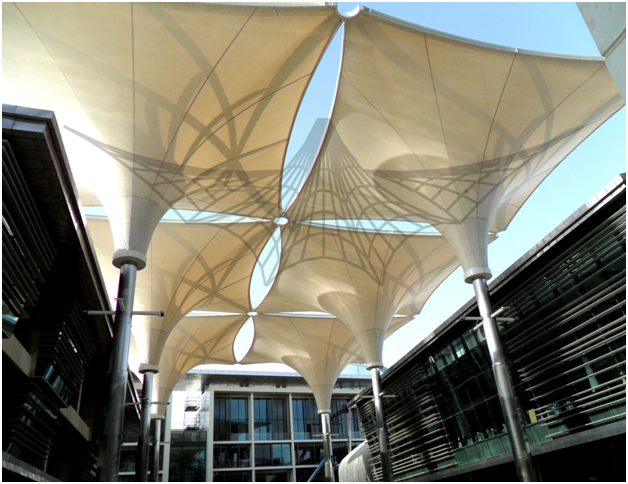

New construction fabrics

Studies of how all this works will inspire man-made materials better able to flex and yet also resist catastrophic buckling under dynamically changing loads. Tensile structures are already a growing feature on our city skylines thanks to innovators such as http://fabricarchitecture.com/; however, as we learn ever more from nature’s example, we can expect greater flexibility, longer spans, lighter weight, and even more creative designs.

Understanding how the bird feather manufactures itself into this intricate and precisely-tuned structure, however, is still one for philosophers to fight over.