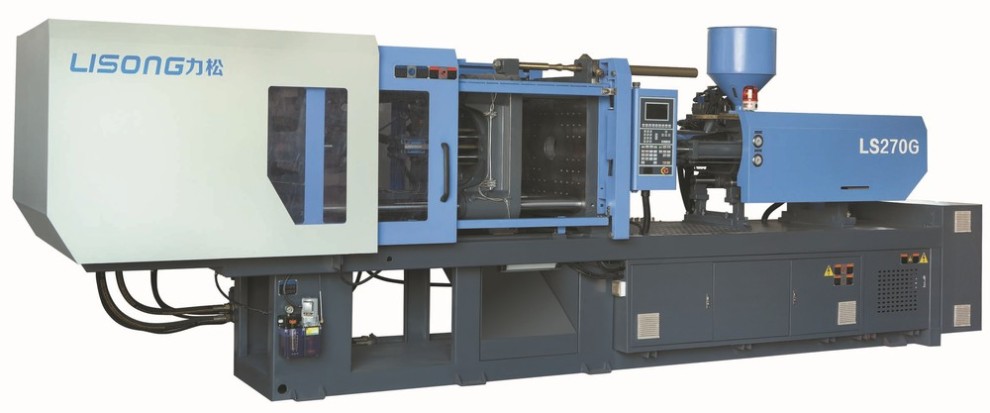

Injection Molding Machine is also known by the term Injection Press. This machine is used for the manufacturing of plastic parts with the help of Injection Molding Press. The two main parts of this machine are clamping unit and Injection unit. These are the very common types of machines, which are used in the plastic industry.

It can easily fasten the mold in both vertically and horizontally way, but you see that 80% of the machines use horizontal way. The process of making the plastic products is quite simple, you just need to heat the plastic, so that it becomes a liquid and then pour this hot liquid inside the mold and after that leave it so that it can cool and after that you should de-mold it.

Types of Injection Molding Machine

There are three different types of the molding machine.

- Hydraulic – It is the most traditional type of machine used in plastic industry.

- Mechanical – These machines use toggle system.

- Electric or hybrid – It’s the latest machine which works more efficiently and quietly. Basically, it combines both the features of hydraulic and mechanical machine.

Purchasing such machines for your company is really very difficult because you want to complete your orders before the deadline and you should not compromise with the quality and performance. You can see that the there are numerous websites, which are selling these machines. It is always advisable to buy these machines only from reputed seller, as they provide good quality product. Also, there are many fake sellers, who are selling such machines in the name of original ones.

Purchasing online can also saves your traveling expenses and time. The plastic injection moulding china is one of the reliable sellers of quality plastic products.

Benefits

Well, there are many benefits of using Injection molding machines and following are some of the most important ones:

- High performance

Injection molding machines are manufactured with the most advanced technology. Also, these are more efficient as compared to the old machines so they never fail when to come to performance.

- Energy efficient

All the parts of these machines are made up of with good material and as these are sophisticated, so they help to save more 70% of the electricity.

- Higher productivity

Because of their high performance and quality of material used in manufacturing of their parts, they ultimately lead to increased productivity.

- Silent and Smooth

Because of their high quality efficient parts, they do not make any loud voice while operating.

- Longer life

Now-a-days, each and every company is designing their machine in such a way so that it can be operated longer without any problem.

- Durable

Besides, performance these molding machines are highly durable because of the material which it is used in manufacturing it and most importantly, it protects the machine from rust.

Therefore, from reading these benefits, it is clear that the injection molding machines are absolutely the correct machine that helps to increase your profits.