A flexible riser is used to transfer resources and material from the sea bed to the drilling and production facilities that are situated at the top of the water surface. Flexible riser can be used to transfer material even from the production and drilling unit to the sea bed. Subsea risers are a part of flexible risers which help in vertical transportation of resources and materials. Risers are basically the medium or the connection between the seabed and the drilling facilities.

- Risers Acts as Pipelines for Transporting Gas

Just like flow lines and pipelines, risers help in transporting produced hydrocarbon and also materials used for production. For example, control fluids, injection fluids as well as gas lifts. Risers can be of two types, rigid or flexible and they are also insulated so as to withstand seabed temperatures.

There are different types of risers that are available like steel catenary, attached riser, pull tube riser, riser towers, top-tensioned riser and also flexible riser. So, how does flexible riser help in material extraction?

- Function of Flexible Riser

This is a type of riser that can withstand and accommodate various situations. These are capable of withstanding both horizontal and vertical movements. They are considered to be ideal for floating facilities. This is originally used to create a connection between the production equipments that are present in a floating facility. But, these days you can find them as primary risers as well.

- Configuration of these Risers

There are a wide variety of configurations for these types of risers. This includes the lazy S and the steep S which make use of buoyancy modules that are anchored. The other configuration is the lazy wave and the steep wave this too incorporates the buoyancy module.

Nowadays, flexible risers are used extensively all over the world for gas extraction. These risers provide more benefit in comparison to rigid risers. Flexible risers are designed in such a way that their life ranges between 20 to 30 years, this is the average life of oil and gas field.

- Reasons for Failure of Flexible Risers

There can be different reasons for the failure of flexible risers. One of the most common is the environmental hazards and also the material fatigue. But, if it is a massive failure then there can be catastrophic consequences both economically and environmentally.

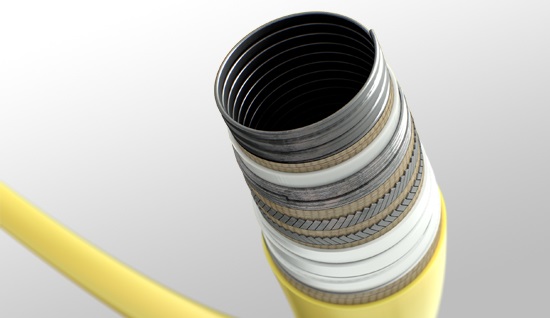

- Layers of Flexible Risers

These risers generally have many layers. But among them the major layers for concern are tensile armors. This main function of these layers is to stand against the tension load. This is also a place for concern because they are surrounded by metallic layers which make it difficult to inspect them. The other layers of flex risers are inspected through radiography. Layers which are metallic, carcass layers and also the pressure armor layer.

- Versatility of Flex Pipe

The reason for it to be called versatile is the fact that it comprises metallic wires and tapes that has helical application. It is also equipped with thermoplastics so as to form a composite structure that has been designed to address various constraints like, water depth, pressure, and fluid characteristics and also the temperature. These risers are of utmost importance in the case of deep-water production and also for deep-water drilling. The static jumpers are used to make a connection between the tension risers and also the floater pipes. This connection is made in the pattern of lazy-wave disposition.

- Reliability of Flex Risers

There is still a cloud of concern over the reliability of these risers. But the failure of these risers is not mainly due to material failures but due to the hazardous environment that is found during deep-water operations. These incidents are only managed and controlled through computer stimulations. So please connect with us today if you want to make Flexible Riser work simpler with totally corrosion resistant for your bore water pumping.